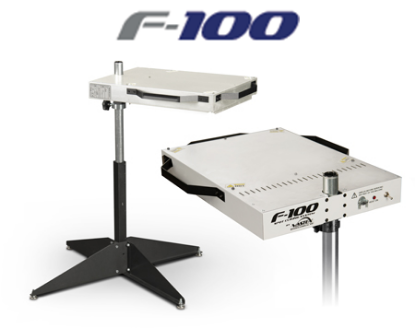

BigRed® 4D Series dryers in 76 and 137 cm belt widths are the largest and most powerful dryers engineered specifically for DTG digital inks as well as screen-printed plastisols, water-based inks, discharge and/or DTF adhesives, making them ideal for Kornit® and other high-volume DTG shops, as well as automatic screen printing operations requiring high capacities, and DTF printing in high volumes. The modular design allows for expandability to easily add chambers and conveyor length as production needs increase.

Model BR4D-V30 with a 76 cm wide belt and four 61 cm wide heaters (total 11,400 watts) cures 72 garments/h printed with DTG/digital white ink at 2.5 minutes dwell time, 216 garments/h with water-based ink or discharge, and 475 garments/h with plastisol ink or DTF adhesives.

Model BR4D-V54 with a 137 cm wide belt and four 122 cm wide heaters (total 22,800 watts) cures 144 garments/h printed with DTG/digital white ink at 2.5 minutes dwell time, 432 garments/h with water-based ink or discharge, and 950 garments/h with plastisol ink.*

For example, a model BR4D-V54 with four heating chambers can cure 576 garments/h printed with DTG/digital white ink at 2.5 minutes dwell time, 1,728 garments/h with water-based ink or discharge, and 3,800 garments/h with plastisol ink.

All BigRed D Series dryers feature a high-powered pre-heating zone that surges ink temperatures past 149°C within the first several inches of conveyor travel, maximizing dwell time at optimum curing temperatures and, in turn, conveyor belt speeds and dryer output.

Air intake fans located below the roof of the enclosure quietly draw 'make-up' air into the chamber's double-walled shell through filtered inlets along opposite exterior sides at rates up to 560 cfm (15.6 m3/min), serving to cool the outer shell for safety, while preheating the incoming air.

An exhaust fan located below the center of the conveyor belt draws the preheated air downward at rates up to 900 cfm (25.5 m3/min), over the garment and through the belt, removing heat, moisture and contaminants from the chamber.

To accommodate each shop's layout, the 152 mm diameter exhaust fan outlet rotates 360 degrees for connection to ductwork, and the control box can be located on the right (standard) or left side of the chamber.

Exhaust filters located on both sides of the conveyor prevent garment lint from entering the blower or exhaust stack. Cleaning all filters before or after each shift can be accomplished in one minute, safeguarding printed images, the equipment and the shop environment.

Exhaust flow sensors with warning lights alert operators to a clogged exhaust line, clogged filter or blower failure. Other safety features include a light tower to monitor dryer status, and a 'cool down mode' for powering down.

Dual digital PID temperature controls maintain accuracy to +/-0.5°C.

The heaters of the BigRed 4D dryers carry a 15-year warranty, and feature closely spaced coils that provide high-density, medium-wavelength infrared heat for maximum cure speed without cold spots or under curing associated with conventional units.

Options

- Additional heating chambers @ 137cm long

- Belt extensions, front or rear @ 46 cm long

- Side heaters to increase "cure zone"

- Control box on left side (right side standard)

- 3 Phase and 208, 380, 480 voltages

- Exhaust hood for extra fume extraction

- Hat support rail

- Locking casters for mobility

- Heavy duty motor drive for conveyor belts

- Donut probe

- Additional heater clearance

.png)